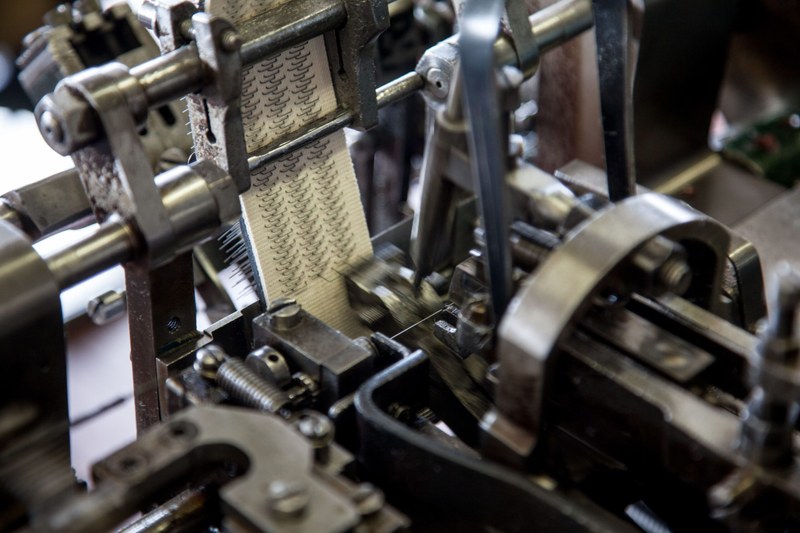

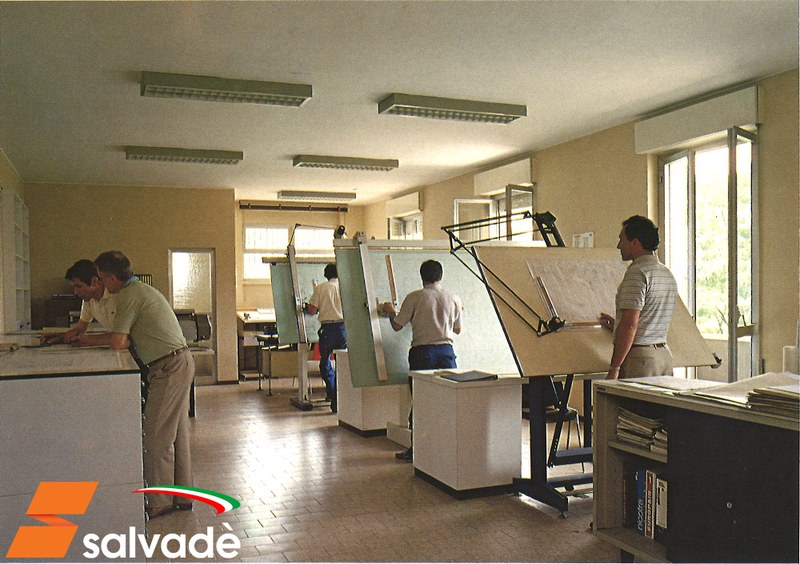

Our specialisation in systems for filtering and removing pollutants from production processes, both those of a solid nature, such as dust and production waste, and those of an aeriform nature such as fumes, oily mists and VOCs in general, is combined with the management of air treatment, serving both processes and the environment. Customized solutions for every need.