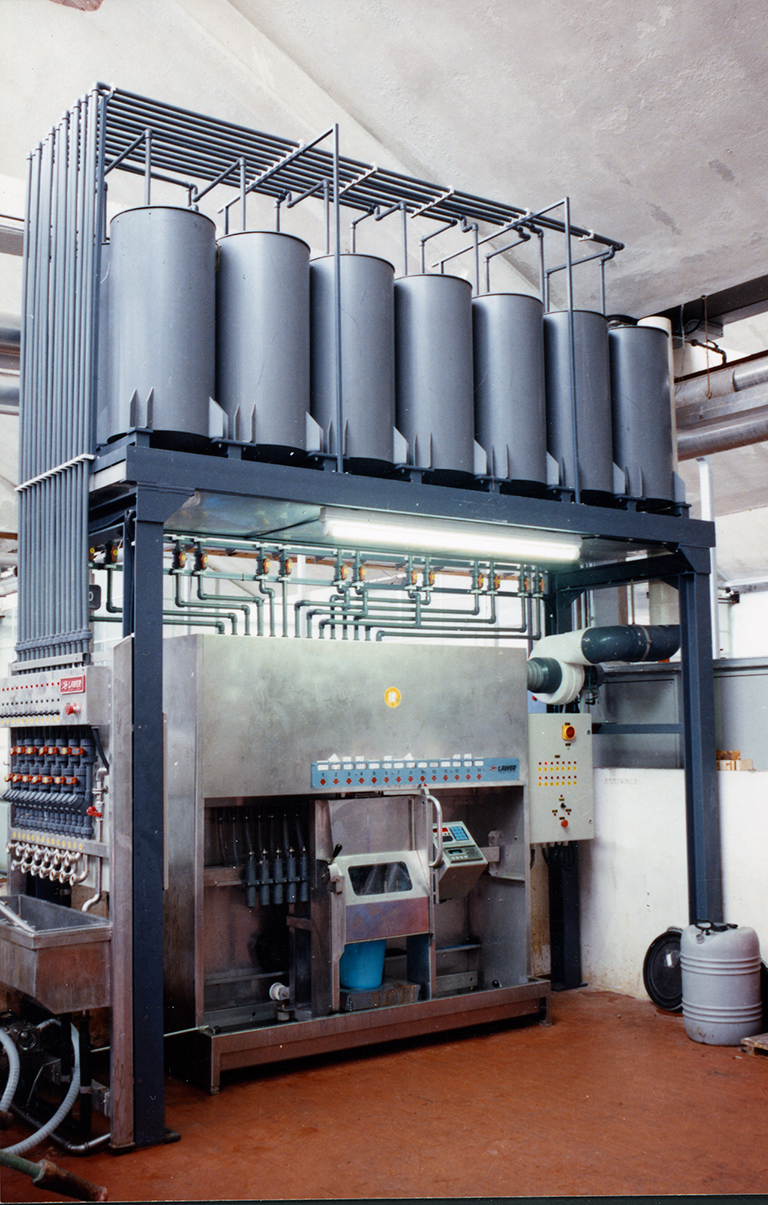

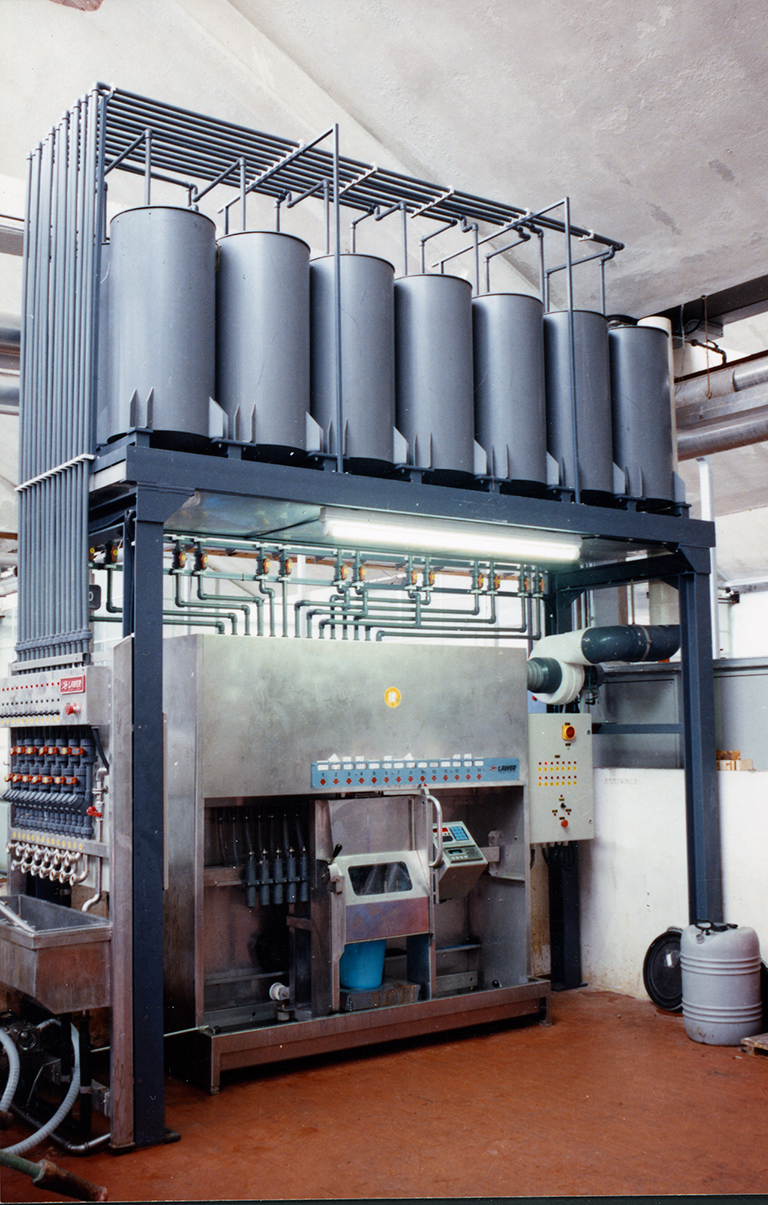

Evaporative cooling represents an efficient and eco-sustainable solution, ensuring:

✔ Greater comfort for operators, with a healthier and more productive working environment,

✔ Important reduction in energy costs,

✔ Better air quality management, with continuous air exchange and reduced suspended dust.