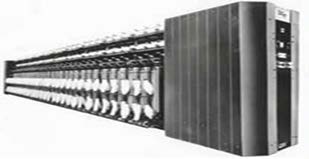

GIUDICI company started its activity immediately after the end of the second world war by means of the founder Davide Giudici who. with the help of his sons. produced parts for the maintenance and the modification of twisting machines for silk. whose processing at that time was widespread in the area of the lake of Como. In 1954 Davide Giudici & Figli s.n.c. was established. a company that distinguished itself by the ability to be abreast of the texturizing market evolution and. in many circuMStances. to be ahead of the times. In 1954 the first twister mod. TG.1 was produced. For the first time the spindles were installed in a line and not in an arched configuration. as it was common. thus reducing energy consumption. The model TG.3 followed immediately after.