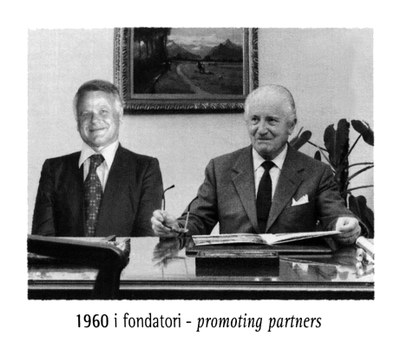

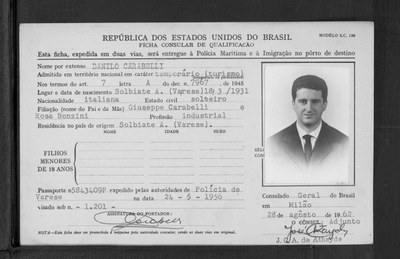

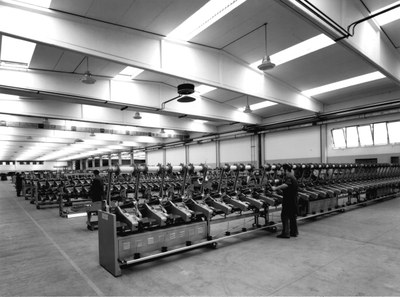

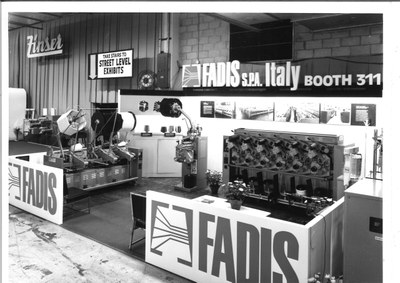

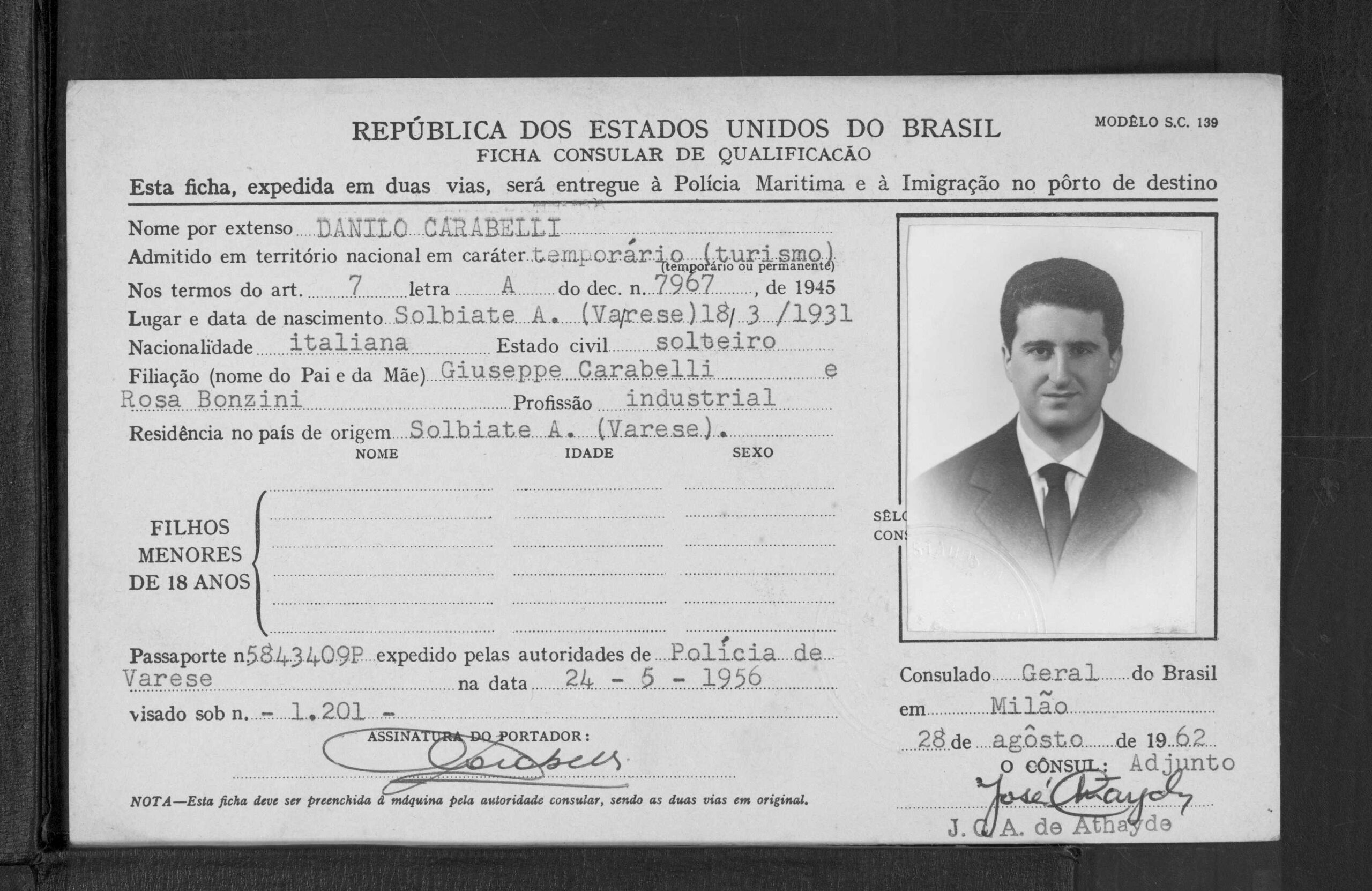

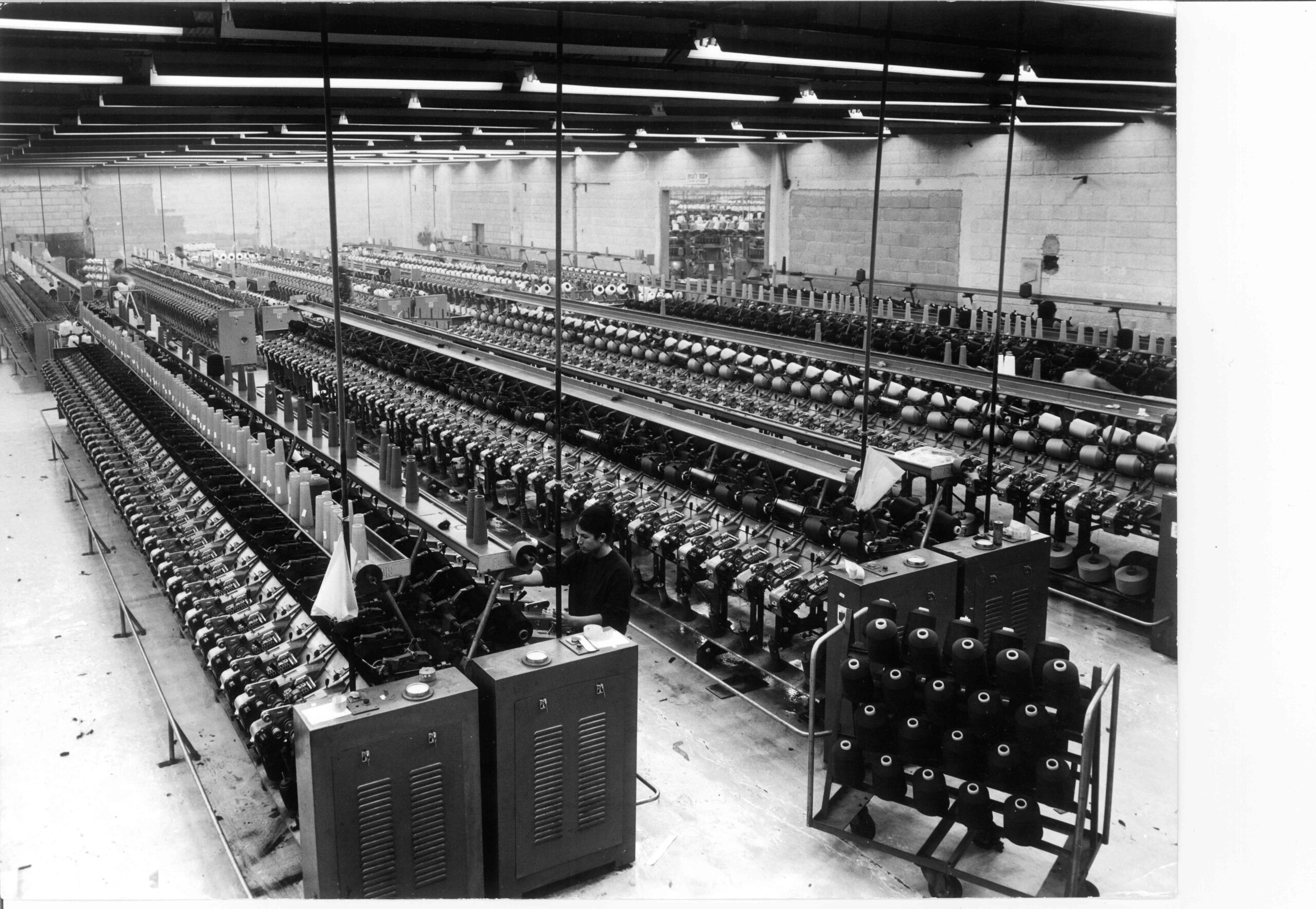

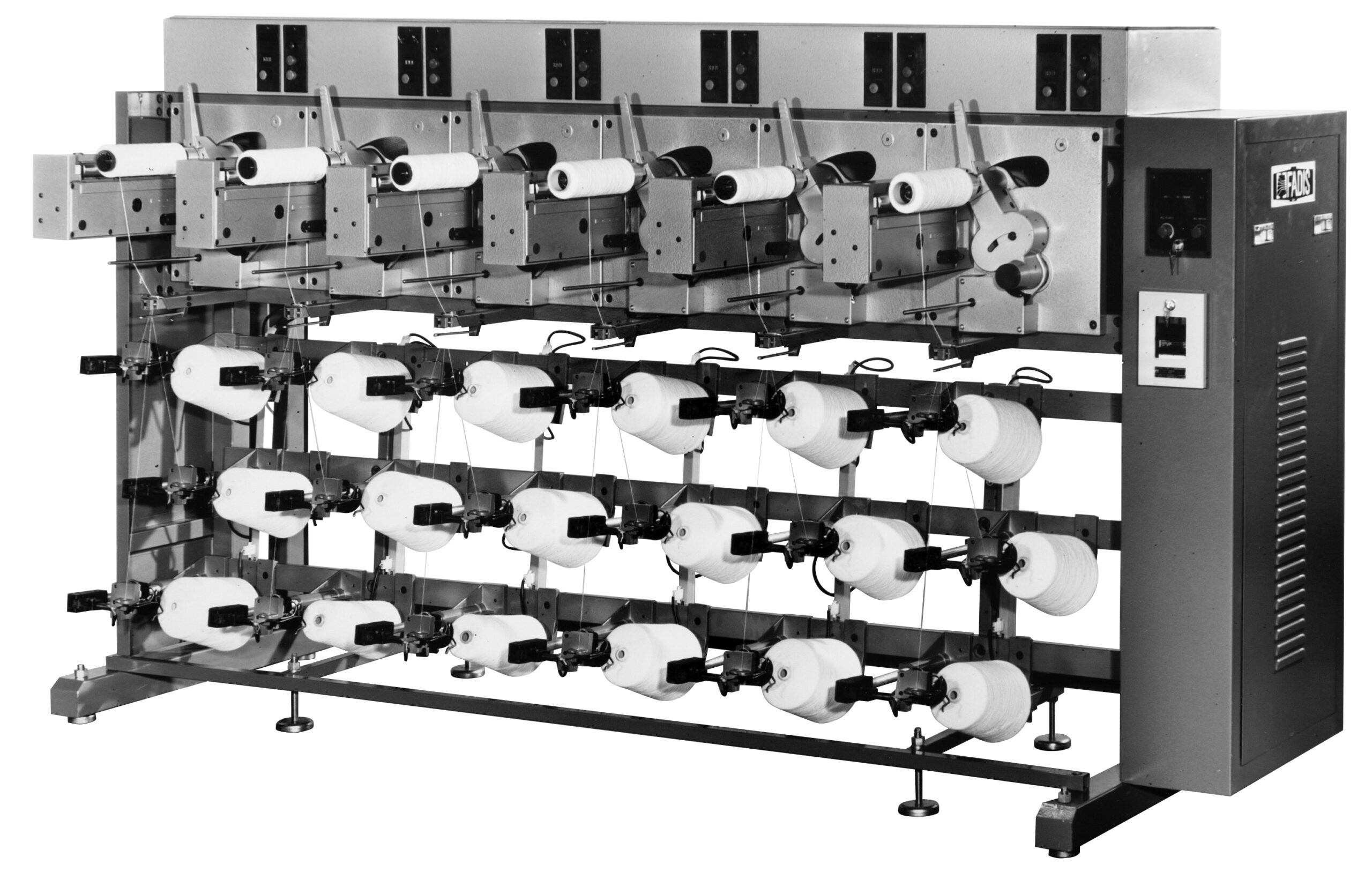

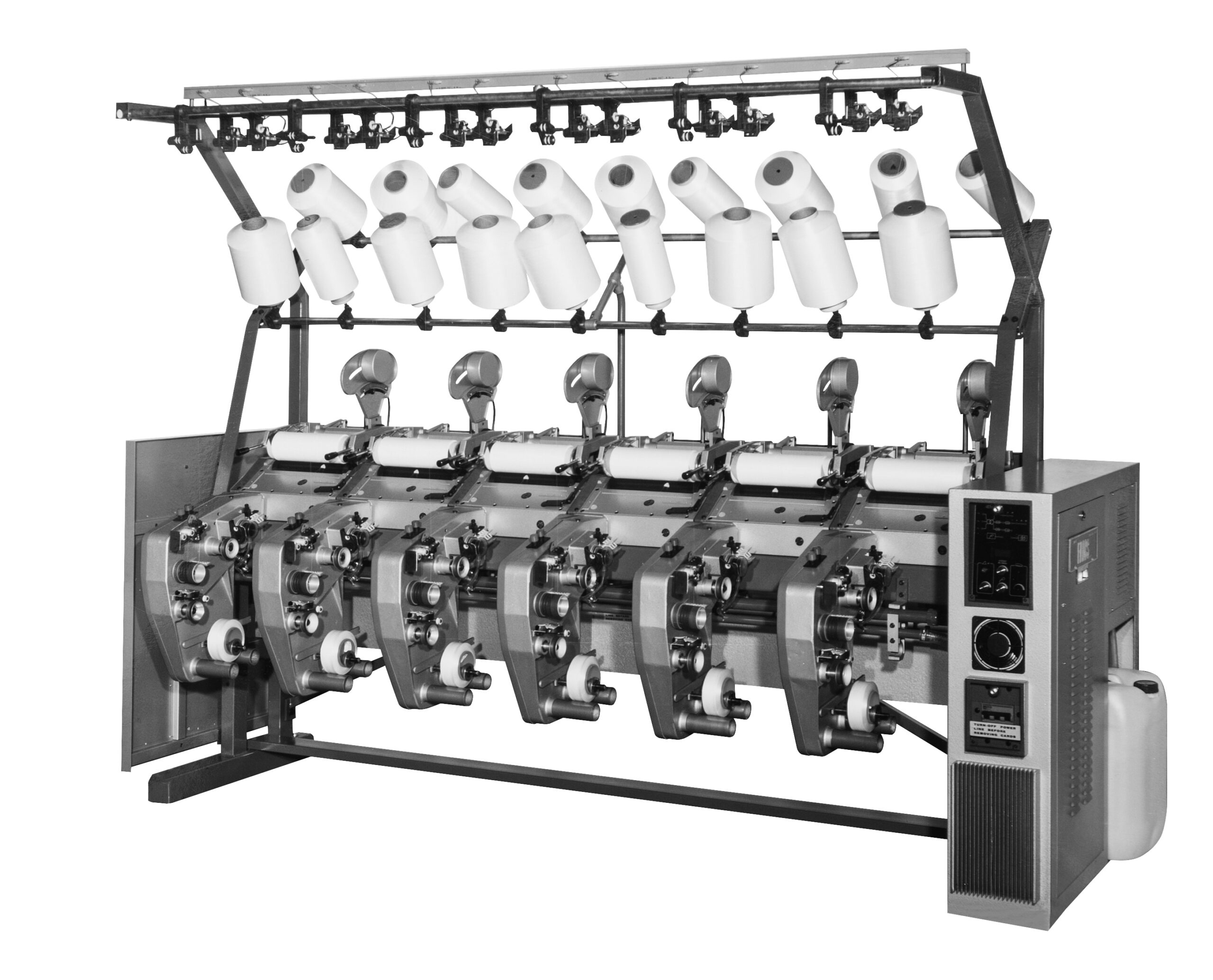

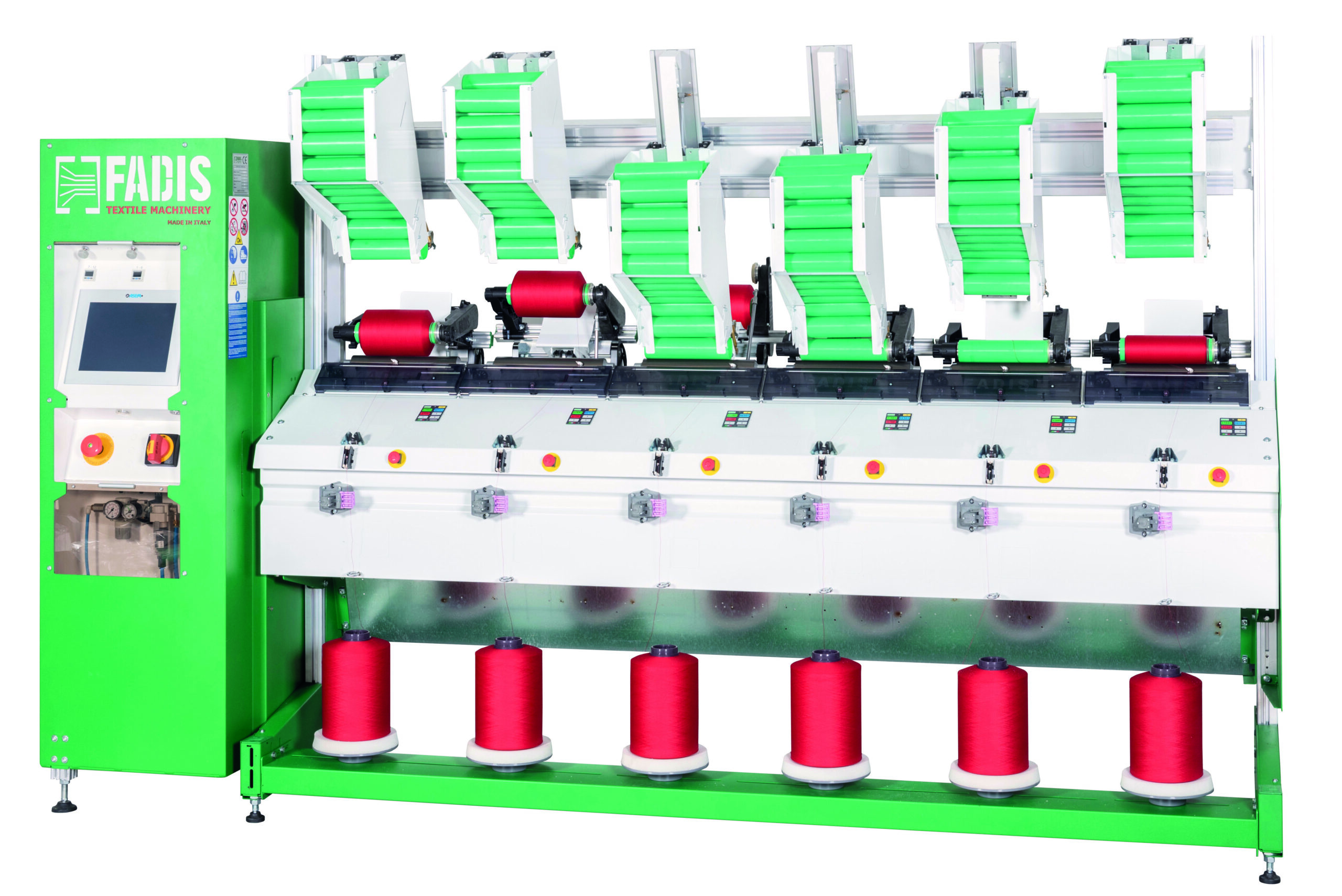

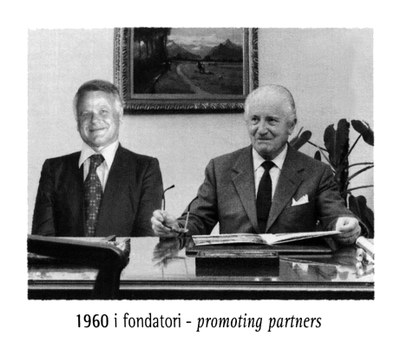

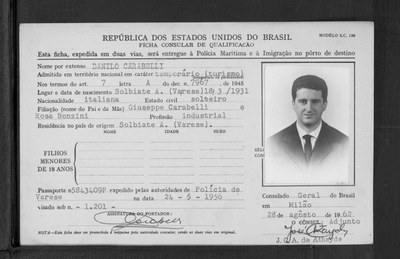

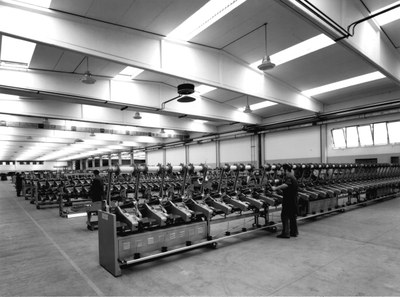

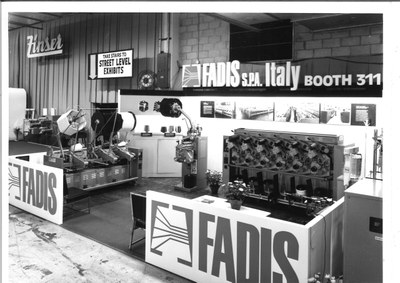

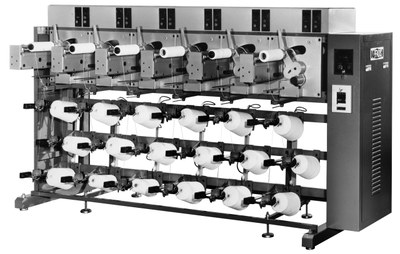

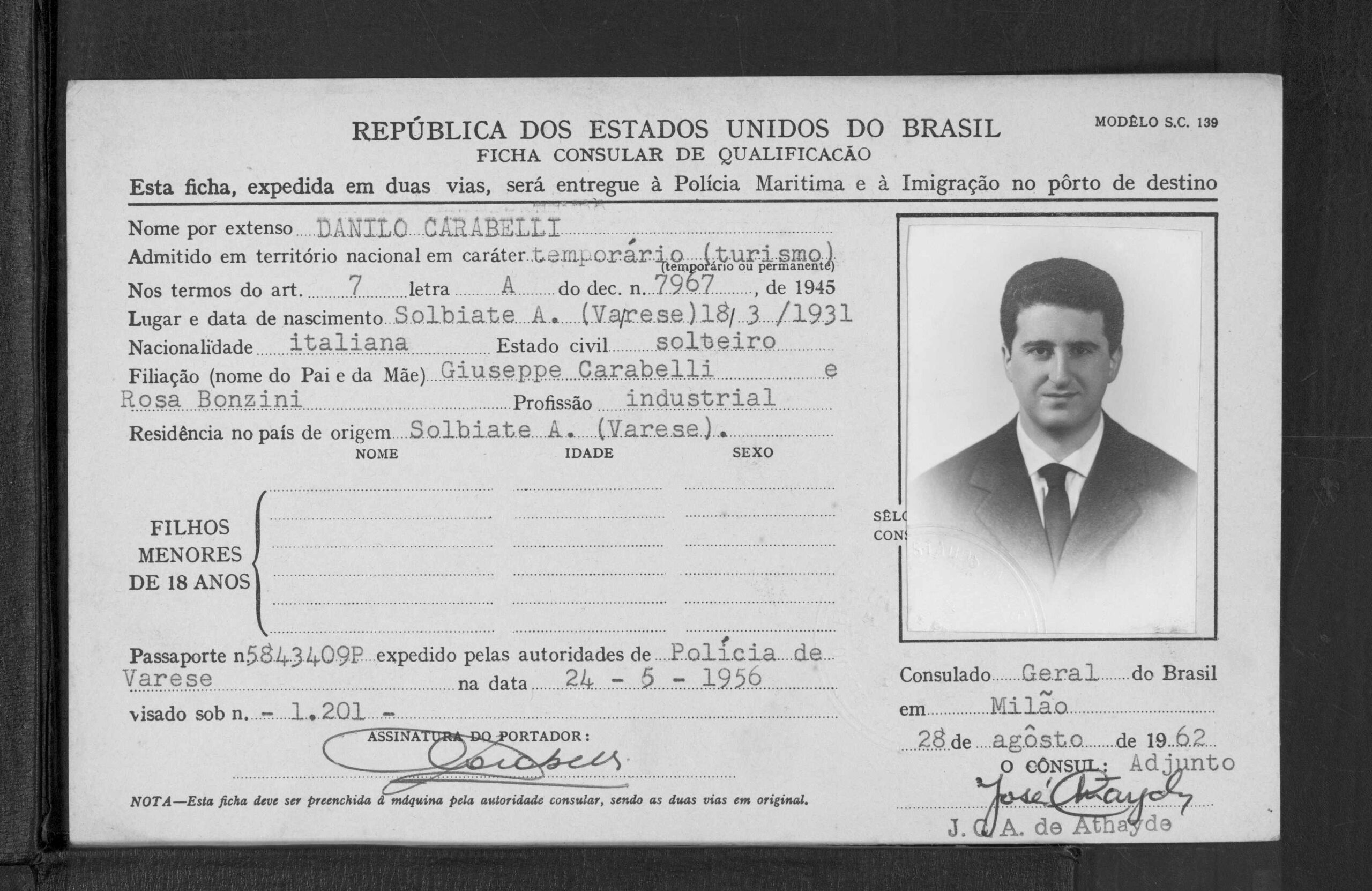

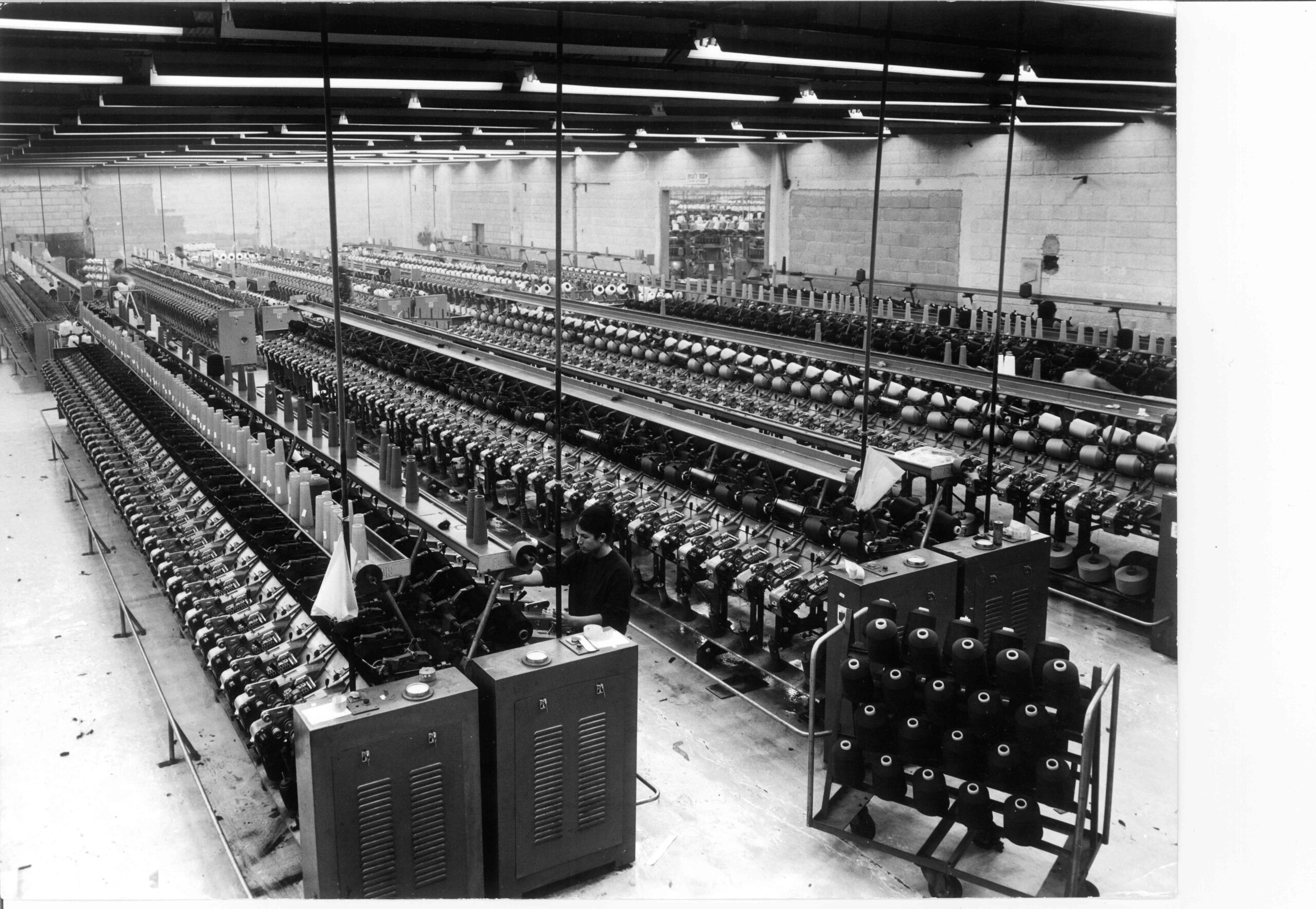

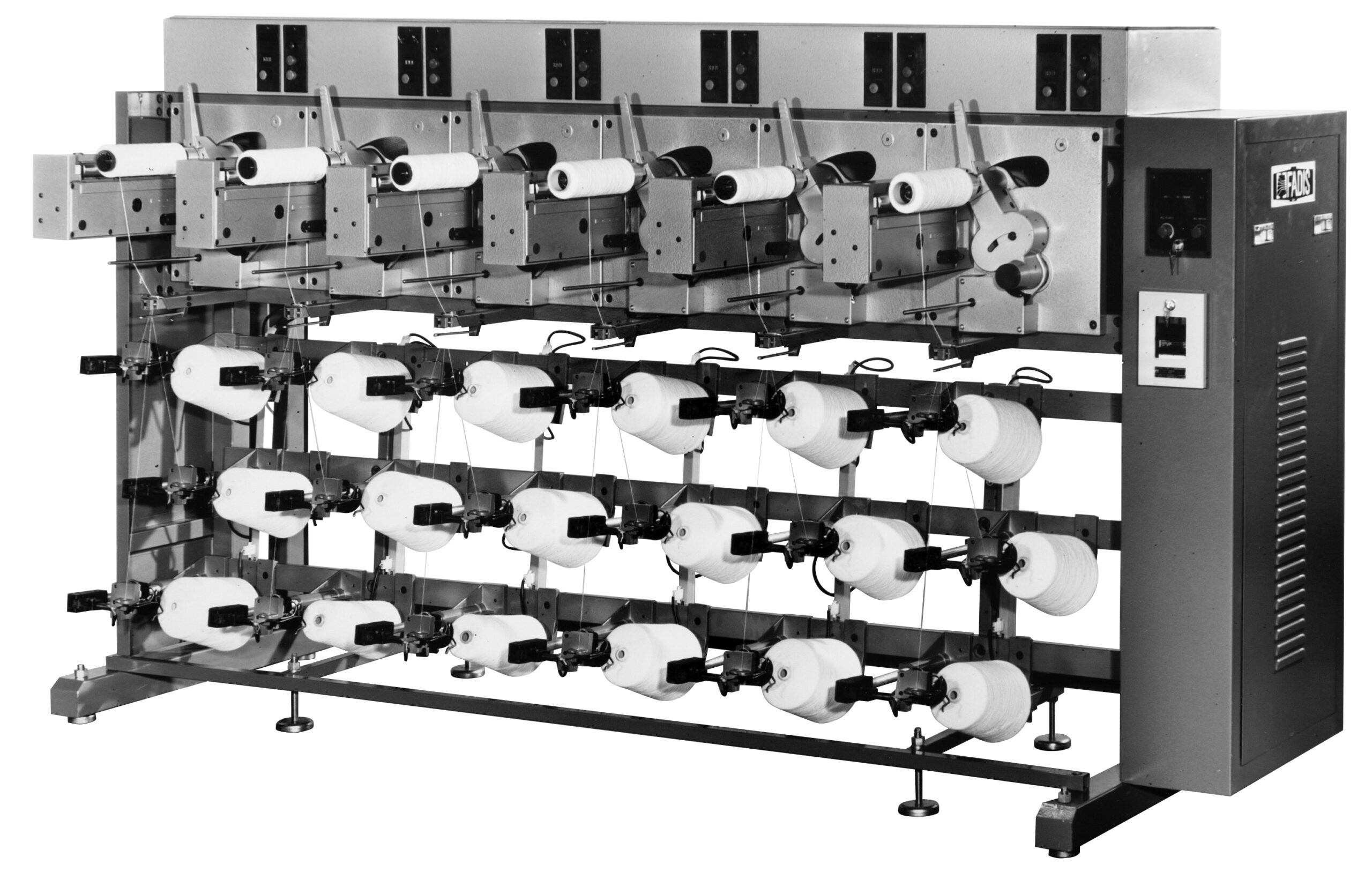

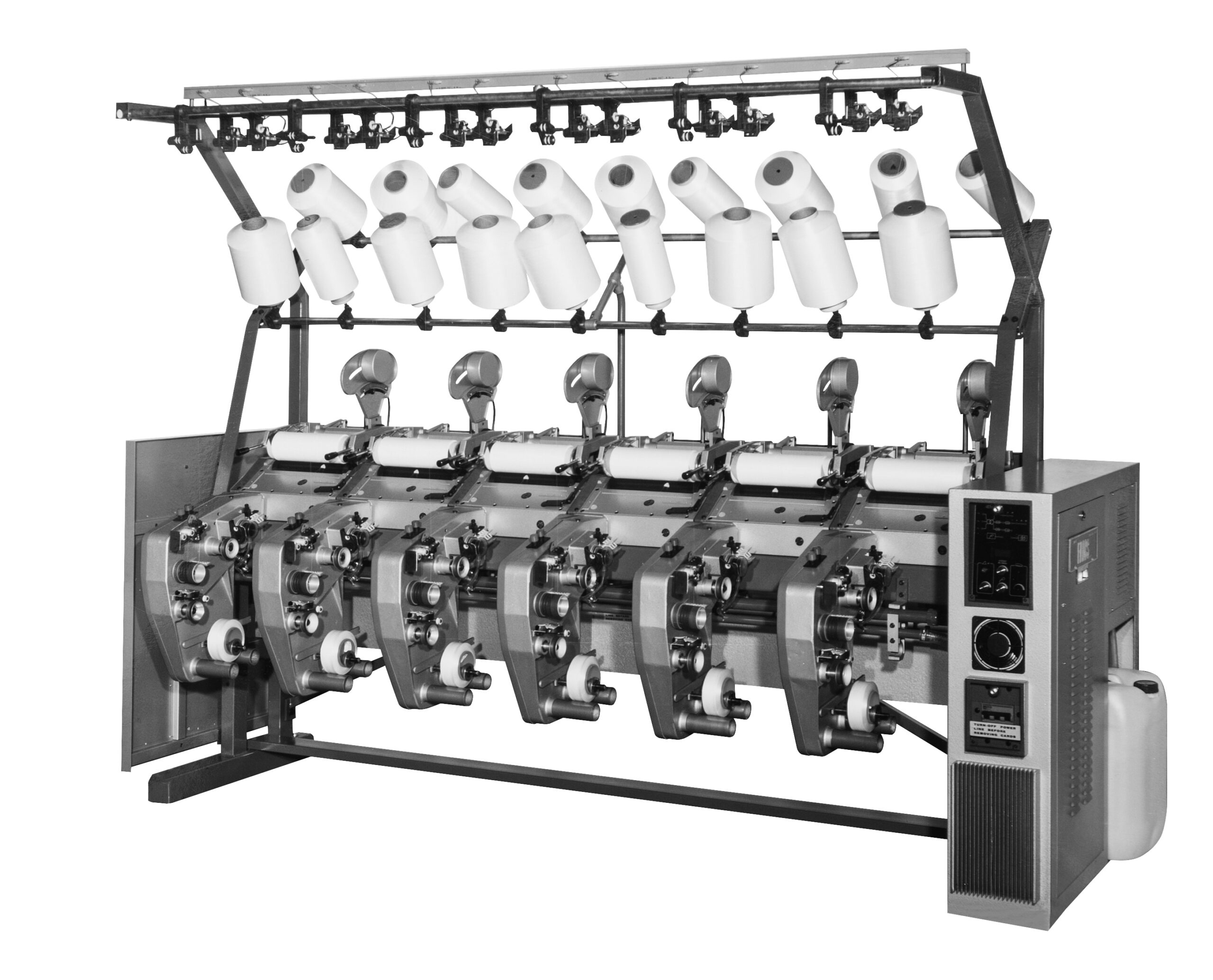

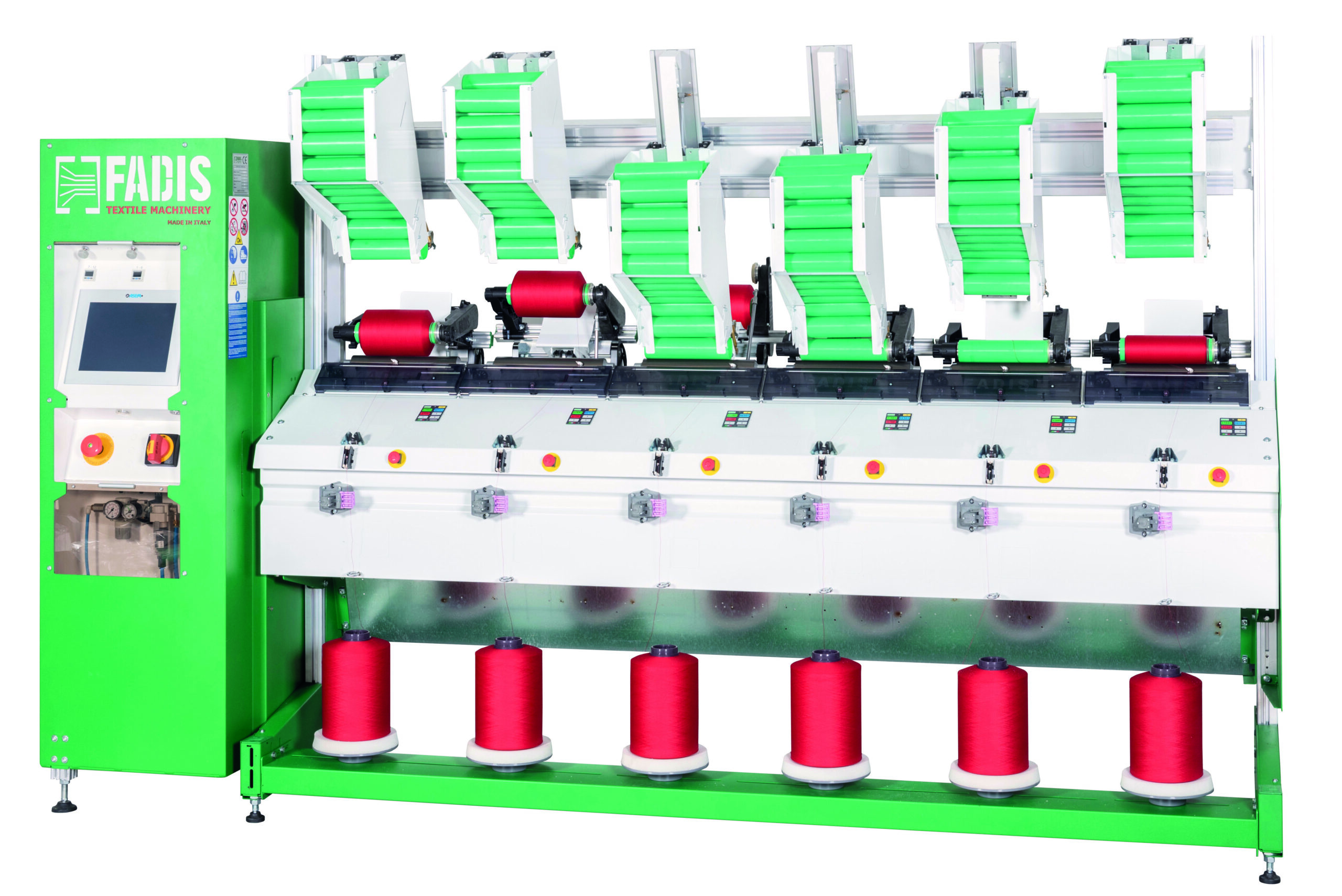

Giuseppe Carabelli with his friend Armando Canton founded Fadis. The focus was on the hank to cone winder and how to modify the machines already on the market .They soon abandoned the idea and started to design a revolutionary machine that eliminated a step in the production. It was the Italian wording for hank to cone winder (dipanatrice) and its location (Solbiate) that gave the business its name (FADIS - Fabbrica Dipanatrici Solbiate) and it's still considered avant-garde. 63 years on.